The V-Pad™ range have been dyno tested and prove to be longer lasting than other cheap sintered aftermarket brake pads. All EBC Organic brake pads now incorporate backing plates which are patented with the Nucap NRS hook retention system. This guarantees zero chance of brake pad de-bonding with corrosion or extended use. EBC recommend these brake pads are not for track or race use.

LEADING BRAKING TECHNOLOGY:

EBC Brakes boast the largest range of brake pads and discs in the world with most of their products produced in their amazing factory in the UK. Developed over 60 years, their range of varying compounds are seen as the best in the business. As well as the huge range of motorcycle products we also offer applications for cars, vans, commercial vehicles and mountain bikes.

PERFORMANCE BRAKE PADS

EBC Brakes offer a huge range of performance brake pads to suit your requirement from everyday road use to regular trackday use.

ATV / Dirt Sintered Pads

Many of us enjoy riding off road with trying to be Malcolm Smith and getting the brakes red hot. For that group the ATV Sintered R series pads are an ideal choice for Off Road Riding. R Series pads are a sintered copper alloy pad made in our USA sintered production plant to deliver a medium to high friction pad, at an attractive price point that lasts well in all conditions of wet, mud water or sand.

Sintered brakes are a very modern and interesting technology, click here to read more about EBC sintered brakes. ATV Sintered R Series pads are equally well applied to two wheel and four wheel machines and as such are very well liked amongst ATV riders especially due to the conditions on some rides where the rear ATV rotor hangs down in the mud and chews through lower quality pads in a weekend. The EBC series pads are available for all modern ATV and Moto X bikes and are priced well below original parts.

R Series pads are also designed for minimum rotor abrasion and will not damage your bikes brake rotors. If you have a wear life problem with an ATV EBC does make an even longer lasting pad with its SV Series Severe Duty range, shown on this page. The SV Series Severe duty brake pad is a High density sintered copper alloy for longest possible life in utility applications on ATV, especially in wet, mud, dust and dirt conditions.

Carbon X / TT Brake Pads

One name always comes to mind when talking about the best in off road riders and our old friend and long time EBC outlet in his shops Malcolm Smith is an avid supporter of the EBC Brakes Carbon X or TT Brakes range and has used them for years in Trail and Enduro riding. Also multi time champ Randy Hawkins has been a long time user of EBC carbon based X pads (or TT pads as we call them in Europe for years.)

Although the Carbon X or TT Brakes will not outlast a sintered copper brake pad it has the unique benefit of lower heat generation and transfer. When riding off road in fast dry conditions such a feature is a major benefit. In our years of listening to the faster riders we have seen cases where the rear brake rotor can be glowing red in night rides which shows just how hot trail braking can get a rotor. Stopping this getting to the bikes hydraulics is greatly assisted by using a Carbon based pad such as the X or TT pad.

Double-H Sintered Superbike Brake Pads

ECE R 90 brake safety approved and TUV tested, these ultra high friction HH rated brake pads remain a market leader above the rest as nothing else beats the performance of the Double-H™ Sintered Superbike Brake Pad.

Manufactured in the US in the state-of-the-art sintering plant in Ohio, Double-H™ Sintered Superbike Brake Pads perform well in all weather conditions be it dry or wet and have a high longevity lasting for many miles..

For race use EPFA or GPFAX sintered ranges should be considered.

Trackday Riding

The superb EPFA range, also fine for fast and heavy street bike use or our

Full Race Closed Circuit

The GPFAX race sintered pad range is the worlds number one Privateer racer choice and used by dozens of Race teams in World Supersport and Superbike racing.

Technical Information

We took out several other particles which our competitors still use which caused massive disc damage and created our launch material. After five years and millions of sets sold we upgraded the formulation again to our SB101C material which completely eliminated BRAKE NOISE, improved the pads HEAT CYCLING CAPABILITY and improved feel. What we have today for the faster rider is the pinnacle of sintered copper alloy engineering, researched and tested in our own laboratories by engineers with over 50 years experience in sintered pad technology.

EBC V-Pads™ Semi-sintered™ Touring Brake Pads

EBC Brakes™ Semi-Sintered V-Pads™ are a new blended Semi-Sintered brake pad that combine the highest qualities of an organic brake pad with the endurance of a sintered equivalent brake pad. The Vee brake pad range are designed for the heavy cruiser/streetbike market as a replacement brake pad.

Features and benefits of these brake pads:

- Heavy streetbike cruiser brake pad

- 100% ECO friendly

- Can be used to replace organic or sintered

- ECE R 90 approved approved and TÜV tested

- Organic compound with longevity

Technical Info

- TÜV German Approved Matl with KBA No. – 60995

- Max. continuous temperature 400°C

- Max. intermittent temperature 600°C

EPFA Sintered Fast Street / Trackday Brake Pads

The USA-made EBC Brakes™ EPFA Sintered Pads for Fast Street and Trackday is a premium long-life street pad with improved fade resistance and heat cycling and improved noise characteristics. EPFA is a great pad for heavy streetbikes, cruisers and faster superbikes as well as intermittent track use. EPFA is a pad group that is as happy on a heavy street cruiser as a fast superbike, a true high-end silent and powerful brake pad.

Sintered Brake Pads

The compound is based on the EBC Brakes™ top selling Double-H™ sintered material with extra friction stabilising additives for improved brake effect and heat cycling.

Many pads feature double segment pad technology which reduces flexing of the backplate and gives better venting to the pad. These pads are German TÜV tested and have ABE certification making them suitable for street use as well as being ideal for occasional Trackday riding. If you require a pad purely for track use we recommend the GPFAX range.

A great value for money high-end option for the rider who just wants the best brakes they can buy.

GPFAX Sintered Racing Brake Pads

GPFAX Sintered Race Brake Pads have by far the highest known friction with a measurement between 0.6 and 0.7 and deliver the most amazing brake effect. Because of this factor, they are unsuitable for street use or for road tyres.

Zero brake fade is guaranteed and the heat stability of these brake pads is perfect leaving the racer with high confidence and a product that can be used over numerous races.

GPFAX Sintered Race brake pads are a closed circuit use pad only and street/highway riding with this material is highly inadvisable and dangerous. Such high friction levels as delivered by these pads are for ideal track conditions with race tyres or slicks on prepared asphalt surfaces and NOT for use with highway tires or on the highway. This material is not ECE R 90 approved nor TUV tested with a German ABE and use on the highway is therefore illegal in many countries.

Statement of Race Use

Racing is a dangerous sport and EBC wishes to advise all users that any and all liability using any EBC products for any kind of Motorsport, track day event or racing lies purely and exclusively with the user. There is no liability or guarantee nor responsibility accepted by EBC brakes or its affiliates or officers for incidents or costs occurring in such race use.

Featured

- ONLY FOR RACE USE

- Highest performance friction level known

- NOT R90 street legal or TÜV tested

- Guaranteed for lifetime performance

MXS Series Brake Pads

EBC MXS series brake pads are moto-x brake pads made in the USA sintering plant with long lasting sintered copper alloy. Perfect for off road race and sport use. Most EBC MXS pads are supplied with new slider pin.

- ONLY FOR RACE USE

- High durability and friction for off road use

- NOT R 90 street legal or TÜV tested

Organic Motorcycle Brake Pads

EBC Brakes™ Organic OE quality replacement motorcycle brake pads are manufactured in the UK using high technology ECO friendly brake pad compounds that deliver fingertip stopping power. With over 40 million sets sold worldwide, the E327 grade organic compound has been a high selling EBC product for over 15 years and is suitable for all road bikes and scooters.

These organic brake pads are now ECE R 90 brake safety test approved and fully TÜV tested. Motorrad Magazine based in Germany rated EBC Brakes™ Organic OE Quality Replacement Motorcycle Brake Pads as being a high quality organic brake pad and they are even now proven suitable as a sintered pad replacement.

SV Series Severe Duty Pads

Designed primarily for ATV use in contaminated riding conditions the EBC SV series pads are a high density version of our successful R series pad blend. Being higher in density these pads last longer than anything else in the EBC family and will stand up against any pad you can buy. They are also very low in rotor abrasion and will not damage your brake rotor. If longest mileage and a pad that will last longer is your target buy, then SV Series is the choice to make.

SXR Side by Side Race Formula Brake Pads

New from EBC Brakes, the SXR side by side range of race formula brake pads are the latest performance offering for the SxS market and deliver unparalleled braking and wear life over standard or other replacement pads.

Made in the USA, the new EBC range is sintered in a custom designed furnace to produce a premium blend of off-road race material that delivers massive friction and heat stability. Resistant to mud, sand and abrasion, the new EBC SXR range is available for all popular SXR models

VLD Limited Edition Chrome Brake Pads

EBC Brakes™ Semi-Sintered Limited Edition Chrome Backed VLD Pads are the same as EBC Brakes™ semi-sintered V-Pads™ but have polished chrome backing plates instead of orange backing plates.

EBC Brakes™ semi-sintered VLD pads are a longer lasting USA made pad with a 30% copper content by weight in a high density matrix to give the best of both worlds –great brake feel and longer life with low heat transfer and less disc damage. These semi-sintered VLD pads are a limited range available for some cruisers and big where extended life may be an advantage. Durability is almost identical to a full sintered pad with great brake performance over a wide range of operating temperatures.

These pads are TÜV approved and are manufactured using the NUCAP® of Canada NRS™ backing plate hook system. This NRS™ system uses small hooks pressed into the surface of the backing plate which bonds the friction material to the backing plate more securely than adhesive bonding.

The NRS™ licence was granted to EBC Brakes™ to help improve the quality of brake pads by reducing the chance of pad separation when the vehicle is used in severe wet conditions.

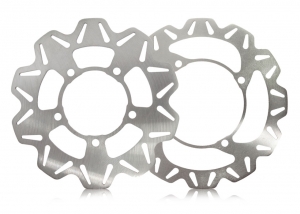

EBC ROTORS

EBC Brakes also offer bespoke race pads for hardcore track applications to provide maximum braking performance.

Floating MC Rotors

Ultra lightweight EBC Brakes X series floating front MC rotors since their introduction, have become one of the worlds best selling lightest and best performing discs available for all modern sport bikes, available from EBC Brakes distributors around the world.

MC Brake Rotors

X and XC Floating MC rotors are the lightest rotors you can buy, they will eliminate all your vibration problems and last longer than conventional rotors using round button technology. Both designs further reduce weight by using only six drive buttons. This further reduces the unit weight by up to 300 grams.

- X rotors feature full circle, circular rotor blades

- XC rotors feature a contoured lighter weight profile.

X Series Floating Rotor

Both Floating MC rotors feature mill hard stainless steel high friction rotor blades for maximum brake effect and are direct size for size replacements for OEM rotors. Both designs are also true fully floating units, offering more inside to outside float tolerance than any other rotor on the planet.

Do not confuse floating rotors with rotors that feature loose rotors blades or buttons. You should not be able to move either the buttons or rotor blades from side to side, if you can, it is highly likely that pad “Knock Back” will occur and you will end up with spongy brakes. Float means outside to inside heat expansion ability. That is what EBC X and XC rotors deliver and no other rotor can.

XC Series Floating Rotor

Floating MC rotors feature EBC Brakes unique and patented S-Drive button system which features square sided rivets captured in square drive pockets on the rotor and hub which allow the outer rotor blade to expand and contract freely under the heat of braking without suffering rivet lock. As the design of Motorcycles progressed over the last 10 years with machines getting lighter, more powerful and faster the demand on Motorcycle brakes has increased. Great technical forward movements such as 4 and 6 piston calipers and more recently the radial caliper have helped stop motorcycles faster but there has been, until now little progress made on brake rotors. There have been attempts to reduce weight on rotors, usually by drilling more holes in the rotor blade but always the OEM builders have used the boring “Round Style” rivet or drive button technology.

This outdated method of building rotors has now been consigned to the history books as EBC Brakes proudly announces the arrival of a new and patented design of drive button known as the SD System. SD stands for Square Drive which describes the button designs used in the new EBC X and XC rotors.

Polished Stainless Rotors for Big Twins

It never ceases to amaze EBC that solid or non floating rotors are still being fitted to modern motorcycles for cost savings reasons when there is such a ready technology with the polished stainless floating rotor for Big Twins at hand to replace them.

Custom Polished brake rotors for American motorcycles The New EBC range of high lustre brake rotors featuring stainless steel brake rotor rings/blades and a polished stainless steel centre hub. Newer units feature the contoured profile and slotted rotor profile as shown opposite which greatly improves pad break-in and reduces rotor damage (rotor galling).

The reason we have opted for stainless steel centre hubs is due to the weight and heavy duty nature of larger American motorcycles often using twin cylinder technology which can lead to more vibration or frame shake.

Complete range of rotors…

EBC produce a complete range of floating rotors for modern big twins and some tasty floating rotor conversions for solid units that will improve your brakes and offset the chance of vibration.

Rotors are all made in the UK using stainless steel usually with polished stainless steel centre hubs and are assembled using the unique EBC SD System square drive button technology. EBC front floating rotors feature 5 or 9 button designs whereas rear rotors can include up to 12 drive buttons to provide a sturdy looking and robust unit worthy of its heavy duty application.

Always use new pads when replacing rotors, the use of old or worn pads can cause hot spots or glazing of the rotor and will promote brake fade and loss of brake.

Oversize MX Disc / Rotors

The Oversize MX Disc / rotor kits installation is a breeze and not only raises braking power by 30% it improves brake control and modulation. That’s why World Top Rider and X Games Champion Travis Pastrana uses and recommends this brake kit See here comments from Travis.

Add to this a set of British made EBC Carbon X or TT pads brake pads for sport riding to reduce heat and deliver fingertip stopping or the new MX-S sintered copper alloy pads made in our own USA factory for the ideal brake pad and a brake set up others will envy.

This Oversize MX Disc / rotor conversion kits is delivered with:

- 280mm Optimum diameter fully floating rotor to replace your stock solid rotor. (Fully floating rotors resists warping better and handle heat and loads better), British laser profiled and built

- Contoured lightest weight profile rotor blade with self cleaning outside profiled curves

- New German Mill Rolled Stainless steel rotor blade and centre with EBC logo centre hub

- Six button stainless steel drive button system

- Billet aluminium relocation bracket designed and made by MX Expert Ted Devol in California

Enduro Rotors

EBC Brakes world leaders in the Motorcycle and ATV brake business are pleased to now offer a new style of brake disc or rotor for Enduro riding.

Known as the EBC Brakes CE series the new rotors are UK made using high quality German mill rolled stainless steel, cast into ingots to EBC specification and precision rolled in Germany.

This unique steel gives a perfect combination of carbon and chrome making it a stainless unit but with heat treatable characteristics perfect for off road use. The chrome in the steel keeps off the rust, the carbon balance allows a perfect heat treatment that offers ductility with strength and avoids heat cracking common with many “Hard as Granite” brake rotors made with conventional steels. No other brake company uses this grade of steel. It is specially cast and rolled for EBC.

VEE-Rotors

This product is fully stainless steel heat treated and tempered back to the optimum hardness. BEWARE – of companies merely stating their product is stainless steel. Some of these are not hardened and of those that are, some are hardened to the excess and can exhibit cracks through over hardness between the holes and edges. EBC has worked long and hard on choosing the exact correct hardness and temper procedure for their brake rotors.

- Fully floating design

- Lightest weight rotor profile

- Features patented SD system hardware

- Black hubs as standard

- Colour options available

CX Extreme Motocross Rotors

Made with tough and durable heat treated stainless steel. These 100% British made units are produced by EBC Brakes in the new Northampton plant using Premium quality German mill rolled steel, heat treated to perfection and then diamond ground to micron accurate surface finish and parallelism and will deliver great brakes at less than Manufacturer prices that will perform and last. Any brake compound can be used but our recommended pad choices are shown below.

- Heat treated and tempered stainless steel

- Lightest weight profile with new Vee design

- Great looks for modern motocross machines

- Balanced front and rear designs

Motocross Contour Rotors

Motocross Contour rotors are 100% British made units are produced by EBC Brakes in the new Northampton plant using Premium quality German mill rolled steel, heat treated to perfection and then diamond ground to micron accurate surface finish and parallelism and will deliver great brakes at less than Manufacturer prices that will perform and last.

Motocross MD Series Brake Rotors

Top selling full circle profile OE replacement rotors made with tough and durable heat treated stainless steel.

These 100% British made units are produced by EBC Brakes in the new Northampton plant using Premium quality German mill rolled steel, heat treated to perfection and then diamond ground to micron accurate surface finish and parallelism and will deliver great brakes at less than Manufacturer prices that will perform and last.

Supermotard Contour Rotor Kit

Upgrade your stopping power with the latest EBC Oversize Supermoto disc kits. Using your standard caliper, the bracket provided, re-position the caliper at a larger radius to enhance braking power and feel over standard disc size.

Easy to install kit takes minutes to fit and gives a significant brake improvement.

- 320mm rotor upgrade kits complete with relocation bracket. To order prefix with SM, example SM6037C

- Most models now made with contoured profile

- Strong and ultra lightweight

- Includes patented ‘Square drive’ button system

- 25% improved braking over standard discs

- Comes complete with billet alloy relocation bracket

VMD Vintage Style Brake Discs

Typically most older Motorcycles that we call classics or Vintage had one-piece solid brake rotors as they were built. These had their drawbacks not least of which is their one-piece construction, they can warp easily.

The EBC VMD series upgrades those brakes to modern technology without a radical change to the looks of your bike and are a direct bolt on with no modifications or brackets, just a clean rotor swap. Original caliper and pads can be retained but we would strongly advise fitting new brake pads. The use of old brake pads on a new rotor is not wise. EBC makes various great compounds to further enhance stopping power shown under our brake pads section

A two-piece stainless steel heat treated and precision ground rotor blade mounted thru stainless steel floating bobbins onto a lightweight aluminium centre hub reduces weight and completely removes all chances of warping and rotor vibration.

Smooth brakes, great looks and lighter weight.